Y-Ring: A Guide to Principles, Design, and Application

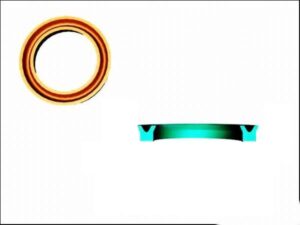

The Y-type rubber seal ring, named for its cross-section resembling the letter “Y”, is a typical lip seal. It is widely used in hydraulic and pneumatic systems for dynamic sealing of reciprocating pistons and piston rods, preventing liquid or gas media from leaking from the high-pressure side to the low-pressure side.

Table of content

- Working Principle

- Design Essentials

- Common Materials

- Installation Precautions

Comparison with O-Rings: Y-rings and O-rings are the most commonly used seals, but each has its focus. O-rings rely on high compression for sealing, have a simple structure, and are excellent for static seals. However, in reciprocating dynamic seals, they are prone to twisting and rolling, leading to wear and failure. The Y-ring, as a representative of lip seals, has a unique advantage in dynamic sealing performance. Through its unique lip design, it generates a “self-sealing effect” under pressure, has relatively low friction, and is less likely to twist and roll during reciprocating motion. Therefore, its stability and service life in high-frequency reciprocating conditions are usually superior to those of O-rings.

Its sealing principle is primarily based on the “Self-Sealing Effect”:

-

Initial Preload: After installation, the root of the seal (the back of the Y-shape) is slightly compressed, generating initial contact stress for static sealing.

-

Pressure Activation: When pressure medium is introduced into the system, it enters the interior of the seal’s lip.

-

Lip Expansion: Under pressure, the lip of the seal (especially the primary lip) expands further, tightly adhering to the sealing groove and the surface of the moving part (e.g., piston rod or cylinder barrel).

-

Tighter with Pressure: The higher the system pressure, the greater the contact stress between the lip and the sealing surface, and the better the sealing effect. This ability to automatically enhance sealing is its core advantage.

Y-rings are typically divided into equal lip and unequal lip (long-short lip) types. The short lip contacts the moving surface and has less friction; the long lip is the support lip, more elastic, and primarily serves to support and prevent rolling.

2. Design Essentials

The design of a Y-ring involves not only the seal itself but also the matching of the entire sealing system.

-

Lip Design:

-

Edge Shape: The lip edge must be sharp and smooth, free of flash, burrs, or wear, which is crucial for effective sealing. A tiny rounded transition is usually designed to prevent damage during installation.

-

Long-Short Lip Design: For directional seals, the long lip should face the low-pressure side, and the short lip (working lip) should face the high-pressure side to achieve optimal self-sealing effect and stability.

-

-

Interference and Compression Ratio:

-

In the uncompressed state, the lip diameter of the seal is usually slightly smaller than the diameter of the sealed shaft or hole, creating a certain radial interference.

-

After installation, the root is compressed by the groove, generating axial compression.

-

The design must accurately calculate an appropriate compression ratio (typically 7%-15%). Too low a ratio will cause leakage; too high a ratio will increase friction and wear, reducing service life.

-

-

Groove Design:

-

The groove width and depth must match the cross-sectional dimensions of the Y-ring.

-

Groove Width: Should accommodate the width of the Y-ring under compression with sufficient space to prevent over-squeezing.

-

Groove Depth: Must ensure the proper compression ratio while positioning the dynamic sealing surface correctly.

-

The groove sides and bottom should have adequate surface finish and be designed with appropriate chamfers and radii to facilitate installation and prevent seal damage.

-

-

Extrusion Gap Protection:

-

Under high pressure, the seal may be extruded into the radial clearance between the piston and cylinder or the piston rod and guide bushing, causing the seal to be nipped and torn.

-

This radial clearance must be strictly controlled in the design, or anti-extrusion rings / backup rings (usually made of PTFE or nylon) should be used to support and prevent seal extrusion.

-

3. Common Materials

The choice of material for a Y-ring depends on the working medium, temperature, pressure, and frequency of use.

| Material | Advantages | Disadvantages | Application Scenarios |

|---|---|---|---|

| Nitrile Rubber (NBR) | Excellent resistance to petroleum-based hydraulic oils, fuels; good wear resistance; low cost | Poor weather and ozone resistance; not resistant to polar solvents (e.g., ketones, esters) | Most common. Suitable for most mineral oils, water-glycol, lubricating oils. Temp range: -30°C ~ +100°C |

| Polyurethane Rubber (PU/AU/EU) | Excellent abrasion resistance, high mechanical strength; high extrusion resistance; good oil resistance | Poor hydrolysis resistance; moderate high-temperature performance | Suitable for high pressure, heavy load, high reciprocating frequency applications. E.g., engineering machinery hydraulic cylinders. Temp range: -40°C ~ +80°C (short-term 100°C) |

| Fluoroelastomer (FKM/Viton) | Outstanding heat and chemical resistance; resistant to most oils and solvents; good weather resistance | Poor low-temperature performance; high cost; low elasticity | Suitable for harsh environments: high temperature, fuel resistance, chemical resistance. E.g., aerospace, automotive engines. Temp range: -20°C ~ +200°C |

| Hydrogenated Nitrile Rubber (HNBR) | While maintaining NBR’s oil resistance, significantly improves heat, wear, and ozone resistance | Cost higher than NBR | Suitable for applications requiring higher performance than NBR, e.g., automotive power steering systems, A/C compressors. Temp range: -40°C ~ +150°C |

| Ethylene Propylene Diene Monomer (EPDM) | Excellent weather, ozone, and aging resistance; resistant to hot water, steam, acids, and alkalis; excellent insulation properties | Not resistant to any mineral oils or fuels | Suitable for hot water, steam, brake fluid (DOT series), dilute acids/alkalis, coolant, and outdoor environments. Temp range: -50°C ~ +150°C |

Other materials like Silicone Rubber (VMQ) (high and low temp resistance, but low mechanical strength) are also used for specific media.

4. Installation Precautions

Correct installation is the final and crucial step to ensuring the sealing performance and service life of the Y-ring.

-

Inspection and Cleaning: Before installation, carefully inspect the seal for any flash, cracks, scratches, or defects. The seal groove, piston, piston rod, and all related components must be thoroughly cleaned of any metal chips, dust, and contaminants.

-

Lubrication: Before installation, apply grease or system operating medium compatible with the seal material to the seal lip and all sliding surfaces. This reduces friction during installation and prevents lip flipping, twisting, or cutting.

-

Use Special Tools: Never use sharp tools (e.g., screwdrivers) to hook and pull the seal. Use installation cones, guide sleeves, or wrap threads, keyways, and other sharp edges with plastic film or thin plastic sheets to guide the seal smoothly into the groove.

-

Installation Direction: For unequal lip Y-rings, ensure the long lip faces the low-pressure side and the short lip (primary seal lip) faces the high-pressure side. Incorrect installation will cause seal failure and even extrusion of the seal from the groove.

-

Smooth Placement: Apply force evenly during installation to ensure the seal enters the groove parallel without any twisting or rolling. After installation, check that the seal is fully seated and lies flat.

Summary: The Y-type rubber seal ring is a mainstay in reciprocating dynamic seals due to its effective self-sealing特性, excellent dynamic sealing performance, and low cost. Successful application relies on accurate understanding of operating conditions, rational groove design, correct material selection (paying special attention to the fluid resistance differences between materials like NBR and EPDM), and meticulous installation.

If you have any questions regarding the design or application of Y-rings, please feel free to contact the technical team at OTE. Leveraging our deep industry expertise, we can provide professional design advice and technical support for your specific operating conditions.

Furthermore, we can offer rapid custom development of Y-rings in various materials and sizes through our efficient R&D system, ensuring your equipment receives the optimal sealing solution.