Find the Perfect Material for Seals & Rubber-Plastic Composites

How to choose rubber material

Selecting the optimal rubber material for your application requires careful consideration of the following key factors:

Temperature Range

High-Temperature Resistance: Determine the maximum continuous or intermittent temperature exposure (e.g., FKM and FFKM excel in extreme heat up to 325°C).

Low-Temperature Flexibility: Assess the minimum operating temperature using metrics like TR10 (temperature retaining 10% elasticity) and Tg (glass transition temperature).

Chemical Exposure

Evaluate resistance to acids, bases, solvents, or specific chemicals. Use the 1-10 Chemical Resistance Score (e.g., FFKM scores 10/10 for aggressive chemicals).

Mechanical Demands

Tensile Strength: Required load-bearing capacity (e.g., HNBR offers 25 MPa).

Elongation at Break: Flexibility and deformation tolerance (e.g., Silicone VMQ reaches 500%).

Abrasion/Wear Resistance: Critical for dynamic applications like seals or belts.

Environmental Factors

Oil/Fuel Resistance: Prioritize materials like NBR, HNBR, or FKM (scoring 9/10).

Weather/Ozone Resistance: EPDM and FKM perform well in outdoor or ozone-rich environments.

Regulatory Compliance

Ensure materials meet industry-specific standards (e.g., FDA compliance for food contact, USP Class VI for medical devices).

Cost-Effectiveness

Balance performance with budget constraints (e.g., NBR is cost-effective for oil-resistant applications, while FFKM is premium-priced for extreme conditions).

Comparison Table of Rubber Material Properties

| Property / Material | Nitrile (NBR) | EPDM | Fluorocarbon (FKM) | Silicone (VMQ) | HNBR | FFKM | TFEP |

| Density (g/cm³) | 1.15 | 0.88 | 1.83 | 1.25 | 1.18 | 2.02 | 1.85 |

| Tensile Strength (MPa) | 18 | 15 | 16 | 8 | 25 | 18 | 20 |

| Elongation at Break (%) | 400 | 450 | 200 | 500 | 350 | 150 | 250 |

| TR10 (°C) | -30 | -45 | -15 | -65 | -25 | -10 | -20 |

| Tg (°C) | -35 | -60 | -10 | -120 | -20 | 5 | -15 |

| Max. Temp. (°C) | 120 | 150 | 200 | 230 | 150 | 325 | 260 |

| Chemical Resistance (1-10) | 7 | 8 | 9 | 6 | 8 | 10 | 9 |

| Oil Resistance (1-10) | 9 | 3 | 9 | 3 | 9 | 9 | 9 |

Notes:

Data Sources: Values are simplified to single-point references from technical datasheets of DuPont (FKM, FFKM), Zeon (NBR, HNBR), Momentive (VMQ), 3M (TFEP), and Aflas (TFEP).

1-10 Rating Scale:

Chemical Resistance:

10: Outstanding (resistant to aggressive chemicals, e.g., strong acids, bases, oxidizers).

9: Excellent (resistant to most chemicals, e.g., oils, solvents).

7-8: Good (resistant to specific chemicals, limited scope).

5-6: Moderate (resistant only to mild chemicals).

3-4: Poor (easily degraded by common chemicals).

Oil Resistance:

9-10: Excellent (long-term resistance to oils, fuels, lubricants).

7-8: Good (short-term resistance, may swell over time).

5-6: Moderate (limited resistance, not recommended for prolonged exposure).

3-4: Poor (rapid degradation or dissolution).

TR10: Temperature at which the material retains 10% elasticity (indicates low-temperature flexibility).

Tg: Glass transition temperature (critical point where material becomes brittle).

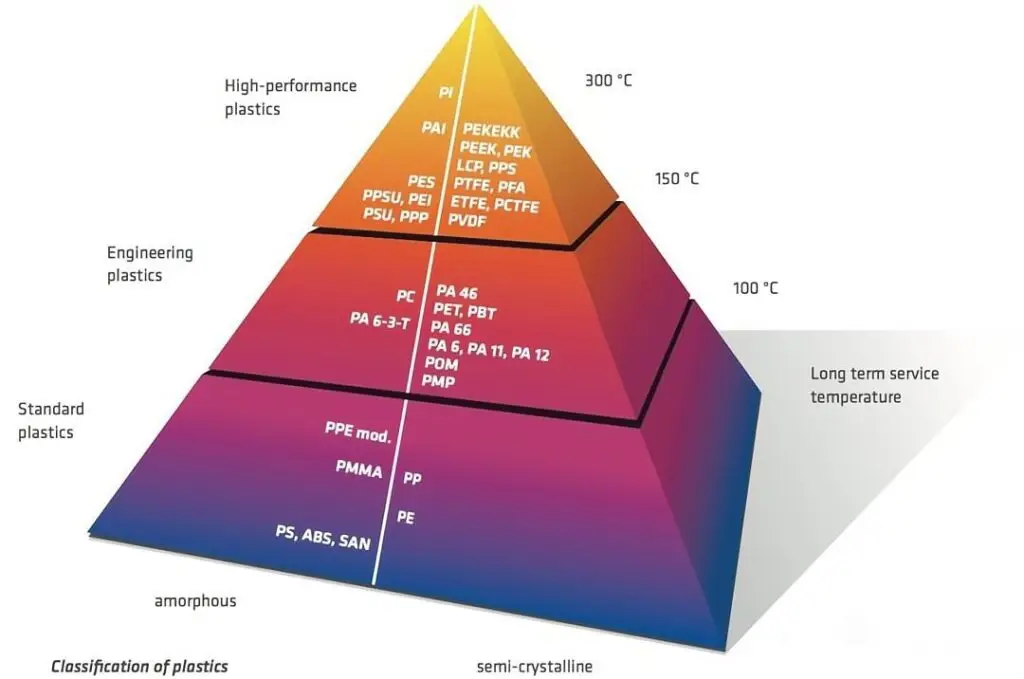

How to choose plastic material?

The following is a comparison table of the common properties of common engineering plastic materials, PEEK, PPS, PTFE and PA66, in the automotive and industrial fields:

| Material | Working Temperature Range (°C) | Water Resistance | Oil Resistance | Chemical Resistance | Advantages | Disadvantages |

|---|---|---|---|---|---|---|

| PEEK (Polyether ether ketone) | -50 to +250 | Excellent | Excellent | Excellent (resistant to acids, bases, and solvents) | High strength and stiffness, excellent dimensional stability, great at high temperatures | Expensive, difficult to process |

| PPS (Polyphenylene sulfide) | -40 to +200 | Very Good | Very Good | Excellent (except strong oxidizers) | Good thermal stability, good chemical resistance, low moisture absorption | Brittle, limited toughness, requires high processing temp |

| PTFE (Polytetrafluoroethylene) | -200 to +260 | Excellent | Excellent | Outstanding (resistant to almost all chemicals) | Lowest friction coefficient, excellent temperature and chemical resistance | Poor mechanical strength, not easily bondable, cold flow issues |

| PA66 (Nylon 66) | -40 to +120 (up to 150 short term) | Moderate (absorbs water) | Good | Good (weaker against acids and bases) | High strength, easy to process, cost-effective | High water absorption affects dimensional stability, lower chemical resistance than others |

Notes:

PEEK is often used in high-end automotive and aerospace applications where temperature and chemical resistance are critical.

PPS offers a good balance of performance and cost, and is common in electrical and under-the-hood automotive parts.

PTFE is preferred in sealing applications requiring extreme chemical inertness and low friction.

PA66 is widely used in automotive connectors, housings, and structural parts where cost and processability matter.

- These plastic materials are usually mixed with glass fiber or carbon fiber for modification; the strength and toughness of the material are improved after mixing.

Please contact for your technical requirement and we could support for the right material selection.If needed, we could optimize the rubber compound for better performance.

FAQ

AFLAS® vs. FKM

AFLAS® (AGC Chemicals) is not an FKM but a TFE/P rubber (tetrafluoroethylene-propylene copolymer), classified under FEPM.

Key differences:

Superior alkali and steam resistance compared to FKM.

Lower fuel resistance but better electrical insulation properties.

Common applications: Geothermal seals, alkaline chemical processing.

What certifications do your materials comply with?

Our rubber compounds meet:

Specialized certifications: FDA-compliance for food-grade applications, USP Class VI for medical devices, and REACH/RoHS for environmental safety.

Custom certifications (e.g., UL, NSF) are available upon request.

Do you offer small-batch production?

Yes, we quote according to your requested quantity. Less qty, higher cost.

Can you develop custom rubber formulations?

Yes! We specialize in tailored solutions for unique requirements:

Adjust hardness (Shore A 30–90), conductive, or flame resistance.

Optimize for extreme conditions (e.g., aerospace cryogenic seals, semiconductor acid baths).

Provide prototypes within 2–4 weeks.

Can you develop custom rubber formulations?

Yes! We specialize in tailored solutions for unique requirements:

Adjust hardness (Shore A 30–90), conductive, or flame resistance.

Optimize for extreme conditions (e.g., aerospace cryogenic seals, semiconductor acid baths).

Provide prototypes within 2–4 weeks.

Do you offer technical support?

Yes, we offer technical support from material selection to mechinical design and validation if needed.