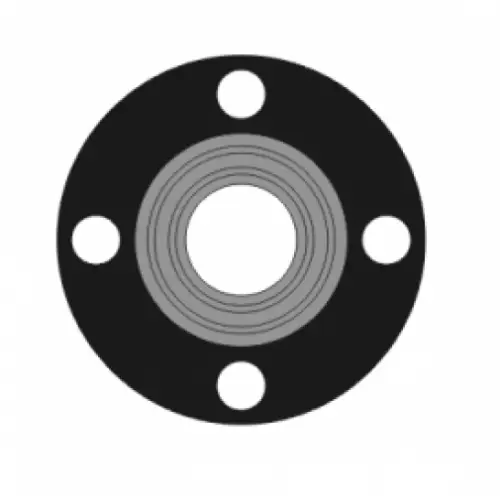

Rubber to Plastic Bonded Product

Rubber materials, as elastomeric polymer materials, are widely used in functional components such as sealing and vibration damping.

Plastic materials, on the other hand, typically offer superior rigidity, chemical resistance, and wear resistance compared to rubber.

By combining these two materials, it is possible to compensate for the limitations of each, enabling the resulting composite to simultaneously meet the requirements for abrasion resistance, chemical resistance, and sealing performance in diverse applications.

Table of content

- Material Property

- Working Temperature Range

- Chemical Resistance

- Wear Resistance

- Typical Applications

Material Property

Here is the comparasion of typical plastic and rubber material:

| Property | PTFE | EPDM Rubber |

| Density (g/cm³) | 2.1 | 1.1 |

| Tensile Strength (MPa) | 28 | 14 |

| Elongation at Break (%) | 10 | 280 |

| Flexural Modulus (MPa) | 800 | 10 |

Working Temperature Range

Normally plastic material have wider temperature range than rubber material. So rubber working temperature need to be mainly considered.

Chemical Resistance

The following is a preliminary classification of rubber’s oil resistance, chemical resistance, and temperature resistance, which can help us choose suitable rubber materials in the design phrase.

Wear Resistance

The wear resistance mainly relies on plastic materials, among which PTFE is a commonly used self-lubricating wear-resistant material. PTFE can also be used as a filler to improve the self-lubricating properties of other materials. But with the regulatory requirements for PFAS substances, we need to consider using other materials to replace PTFE.

| Material | Key Characteristics | Typical Applications |

| PTFE (Teflon) | Extremely low CoF, self-lubricating, normally filled with carbon fiber for wear resistance. | Bearings, seals, non-stick coatings. |

| POM (Acetal/Delrin) | Low moisture absorption, high stiffness, and good wear resistance in dry environments. | Precision gears, pump components. |

| PEEK | High-temperature stability, chemical resistance, and excellent wear performance. | Aerospace, automotive, and oil/gas components. |

Applications

- Automotive – Cooling System

- Automotive – Fuel System

- Chemical Industry

Thanks to contact us to discuss your requirements regarding O-RINGs. We are ready to assist you with fast, reliable support.